CORTEN is a special type of construction steel, which is able to protect against corrosion with own rust like patina that is created after being exposed to weather conditions. It is not necessary to use any paint or other anticorrosion finishing. After few years outside will the corten steel adopt characteristic rust like color that is afterwards stabile and does not stain.

Actually the corten steel is let to „corrode“ on the surface to prevent the steel from further corrosion.

Historically, the first mention of a patent adding copper to steel to improve its corrosion protection dates back to 1822, but it was not until the twentieth century that research began and it was found that adding 0.03% copper effectively improved steel resistance against corrosion. Behind this discovery was Mr. Kendal and Henderson from USS Steel company, who in 1933 called the steel with the addition of copper Cor-ten and began to promote it under that name.

In the following years, research began with combinations with additional elements added and the number of tests increased, resulting in the addition of other elements to copper such as Si- (silicon), P- (phosphorus) and Cr- (chromium). Subsequently, two variants were put into practice – with Nickel (Corten A) and without Nickel (Corten B). In the United States, 20 years of research have been conducted into oxidation in different atmospheres.

The ASTM Commission has issued standards for a number of copper-alloy steel alloys for their application without surface treatment by painting and galvanizing for bridge structures, where the steel must be able to withstand outdoor conditions for at least 100 years.

One of the examples is famous New River Gorge Bridge made of the corten steel. You can read of the history of this world known structure here.

The Corten sheets we offer are manufactured in the best and most modern ironworks in Europe to a standard that we believe to be the most modern and most advanced form of this type of steel. We can offer sheets and coils in qualities Arcorf, S355J2WP; S355J0WP.

Please contact us for specific specifications and current stock thickness.

Our supplier started the specialized production of Corten welded profiles and pipes in 2016 from the parent coil, which gives the pipes the same properties as the sheet and therefore there is no contamination by other types of corrosion. In this way, the properties of the Corten material can be guaranteed, since when different materials are combined the properties of the Corten may be altered. We offer pipes in S355J2WP quality.

Pipes are available with wall thicknesses of 2 and 3 mm. In addition to the standard dimensions, we can also provide dimensions based on your needs. Please do not hesitate to contact us for more detailed information and conditions.

To work with Corten steel, special welding electrodes for this type of steel are required. In our offer you will also find chemicals to accelerate oxidation and also topcoat varnish for interior and exterior use.

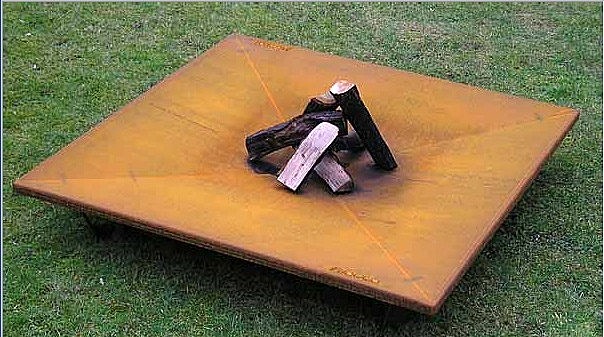

The weather resistance of the steel gives it special characteristics. It can be placed outdoors without any maintenance, so you can leave architectural and artistic elements such as sculptures, wall coverings, fencing, railings, garden furniture, aesthetic and functional elements in the garden (lawn separators, tree posts, flowerpots, fountains, etc.) without any maintenance, and within 6-8 years without the use of an accelerator, the patina formed will stabilize and color to its final form. All this without the need for painting or further maintenance.

Sheets are available in widths of 1000, 1250 and 1500 mm. Not all grades are available in all widths. The length can be 2000, 3000 and 6000 mm. We can also offer non-standard lengths exactly according to the customer’s needs.

Standard material thicknesses are: 1.5, 2, 3, 4, 5, 6, 8, 10, 12 mm. On request we can deliver Corten sheets up to 20 mm thick.

For standard round, square and rectangular pipe sizes, see PIPES section.

The oxidized corten steel surface forms a layer that prevents water and water vapor from entering the material, preventing further oxidation of the material and therefore no protection of the steel against weathering such as galvanization or coating protection is required.

The main purpose of creating this material was to have a construction steel that does not require any treatment or other attention for years.

Surface corrosion is created on the materials due to the effects of weathering, so that for interior use the material needs to be oxidized by chemicals designed for this purpose. It is not necessary to use any accelerators for outdoor use, the protective layer will be created according to the specific conditions at the application site within 8 years. During maturation, material that has been allowed to corrode naturally without the use of chemistry has different shades of patina formed. If the desired result is approximately solid, we recommend applying an oxidation accelerator. Surface painting is really at the customer’s request and the desired finish and end result.

The surface layer is not able to form within 200 meters of the sea level due to the effect of salt particles in the air. These salt particles will prevent a continuous layer against corrosion patina from forming and the material will corrode. Thanks to the added alloy elements, the material corrodes at sea is 8-10 times slower than ordinary steel.

You can read more about corrosion-resistant Corten steel on Wikipedia.

LLZ Servis, s.r.o.

Stará Vajnorská 39

821 04 Bratislava

+421 2 4363 3024

obchod@llzservis.sk

info@cortenspecialista.sk

+421 911 449 122 - Corten specialist

+421 911 449 120

+421 911 449 162